The WSP approach is flexible to suit all types and sizes of water supply systems, and can be effectively applied in all socioeconomic settings.

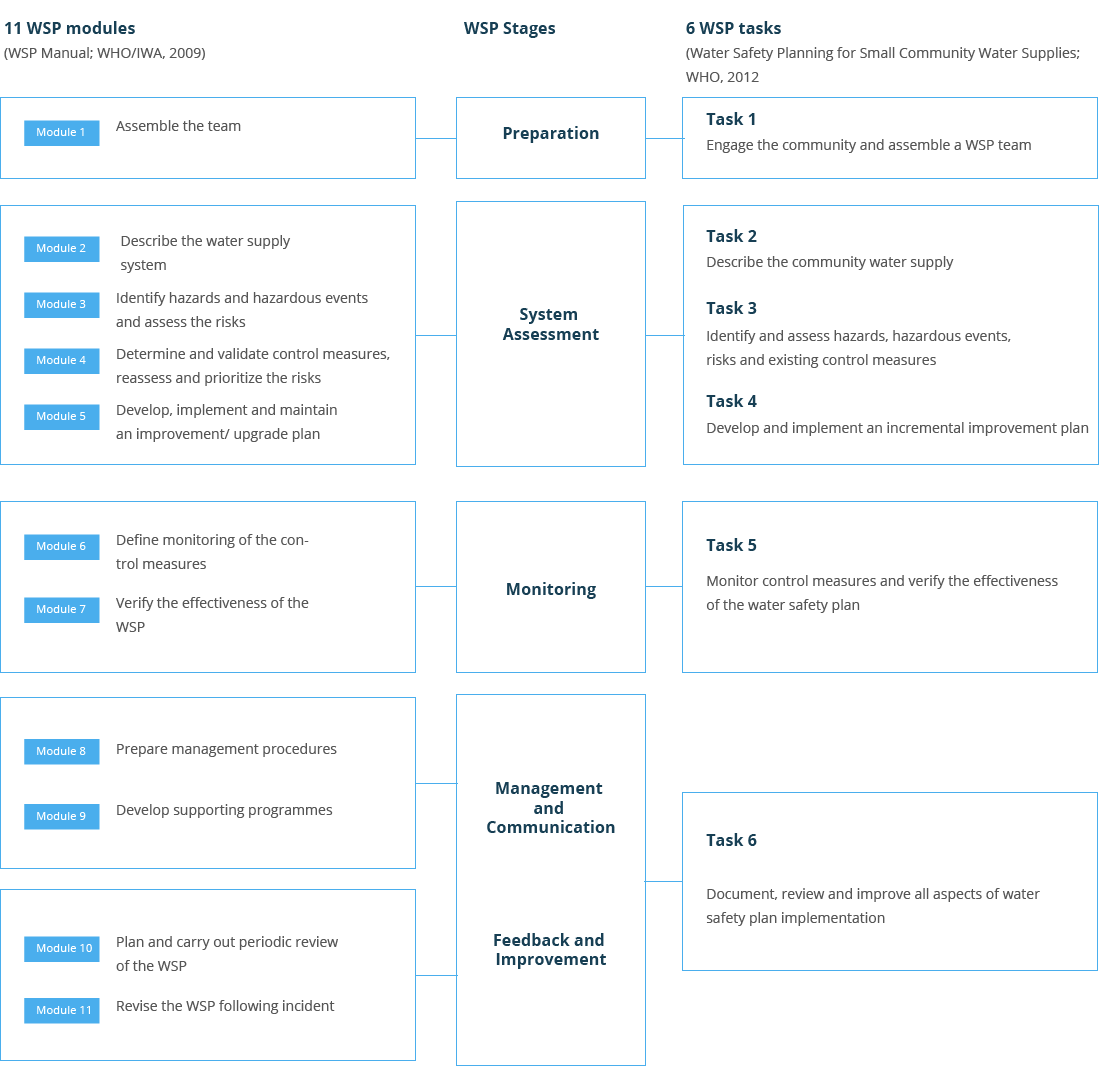

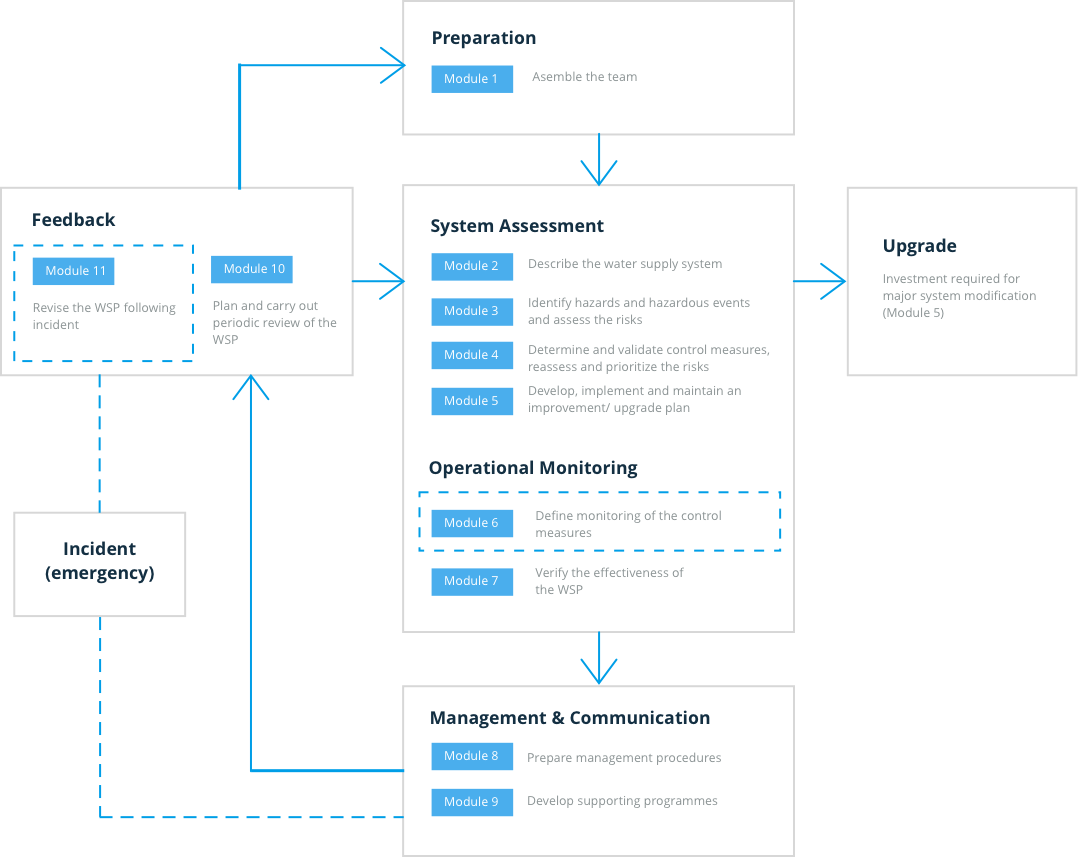

To guide the development and implementation of WSPs, 11 modules (or steps) have been developed. This approach is commonly applied to urban water supply systems.

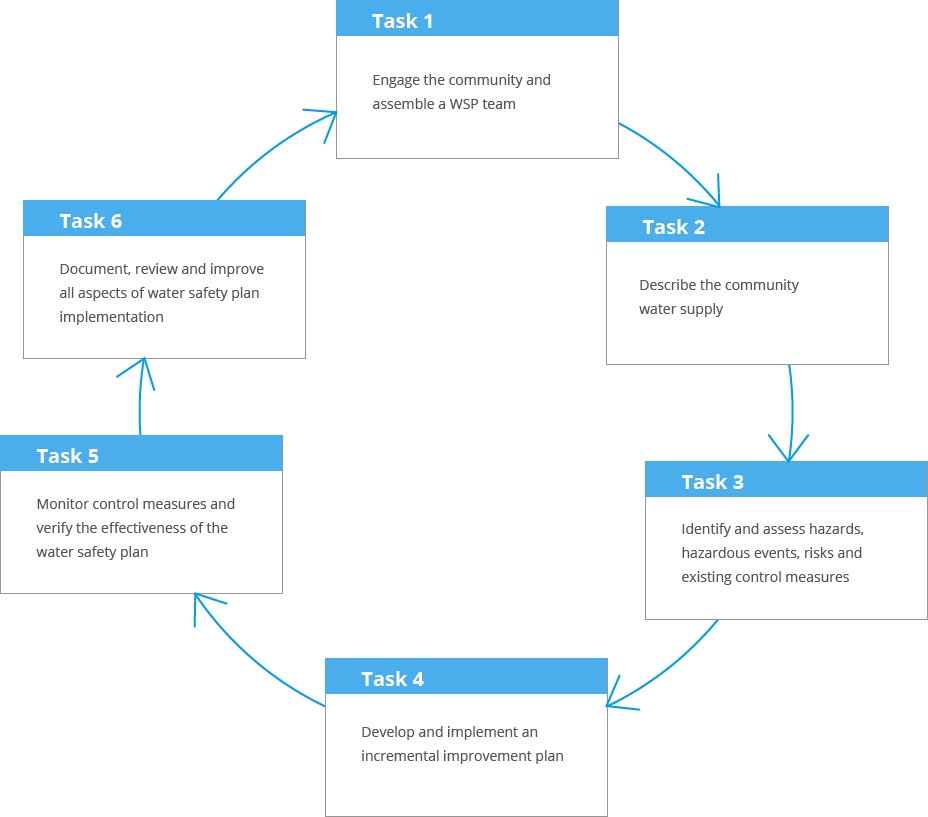

To guide water safety planning in small water supplies (including rural settings), a simplified approach has been developed, consisting of 6 WSP tasks.

Click on the tabs below for a brief overview of the WSP approaches

- Urban

- Small Water Supplies

- Comparision of Urban and Small Water Supplies

11 WSP Modules at a Glance

Click here to download a complete summary of the 11 WSP modules.

- Module 1

- Module 2

- Module 3

- Module 4

- Module 5

- Module 6

- Module 7

- Module 8

- Module 9

- Module 10

- Module 11

Module 1: ASSEMBLE THE WSP TEAM

Establish a multidisciplinary team with the technical expertize needed to develop, implement and maintain an effective WSP. Appoint a strong team leader and clearly define the roles and responsibilities for each team member. Engage senior management to secure their support for development of the WSP and, where necessary, identify which external stakeholders and expertize may be required.

For further information on this module, see the Water Safety Plan Manual (WHO/IWA, 2009).

Module 2: DESCRIBE THE WATER SUPPLY SYSTEM

Provide a thorough and accurate system description of the complete water supply chain, from catchment to consumer, with sufficient detail to facilitate hazard identification, including:

- written description of all major process steps

- system flow diagrams / schematics

- description of intended users and uses of the water supply

- comparison of water quality standards or targets with water quality achieved in practice.

For further information on this module, see the Water Safety Plan Manual (WHO/IWA, 2009).

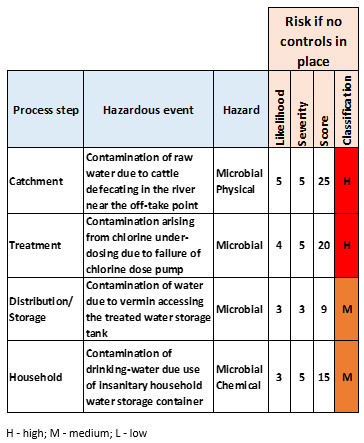

Module 3: IDENTIFY HAZARDS AND HAZARDOUS EVENTS AND ASSESS THE RISKS

For each step in the water supply chain, identify hazards and hazardous events that threaten the safety of the water supply, and assess the associated risks.

Hazard: A chemical, physical or microbial agent that can cause harm to public health.

Hazardous event: An event or situation that introduces hazards to, or fails to remove them from, the water supply.

Risk: The likelihood that a hazardous event will occur combined with the severity of its consequences.

Part 1 - Identify the hazards and hazardous events: The description of the hazardous event should be specific, clearly describing what can happen to the water supply system and how it can happen (i.e. cause and effect). It may be useful to use the following basic formula when describing hazardous events:

X happens (to the water supply system) because of Y

For example:

The source water is faecally contaminated (X) due to fertilizer use on crops and runoff during rains (Y)

Part 2 - Assess the risks:The risk associated with each hazardous event should be assessed to distinguish between significant and less significant risks.

Important distinction - This first (or ‘initial’) risk assessment does not consider any preventative control measures that are already in place. Consideration of existing control measures in the risk assessment takes place in Module 4.

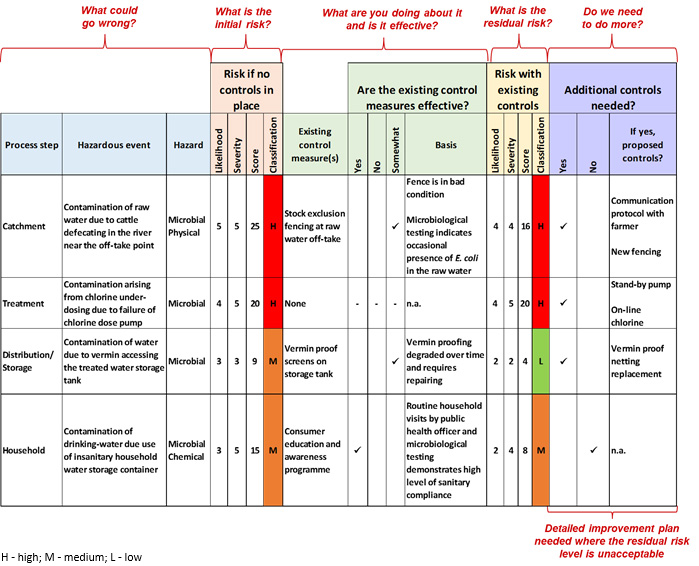

Example of a table from a WSP to document hazards, hazardous events and the subsequent risk assessment:

For further information on this module, see the Water Safety Plan Manual (WHO/IWA, 2009).

Module 4: DETERMINE AND VALIDATE THE CONTROL MEASURES, REASSESS AND PRIORITIZE THE RISK

Control measures: Activities or processes to prevent or eliminate a water safety hazard, or reduce it to an acceptable level (also known as ‘barriers’ or ‘mitigation measures’).

Validation: The process of obtaining evidence that the control measures can effectively control the hazard.

Part 1 - Identify the existing control measures for all hazardous events identified in Module 3 and validate their effectiveness.

Important distinction - Module 4 focuses on the existing control measures that are already in place, whereas Module 5 focuses on documenting new or additional control measures that are required.

Part 2 - Reassess and prioritize the risks, taking into account the effectiveness of the existing control measures. This second (or ‘residual’) risk assessment considers the effectiveness of the existing control measures and allows the WSP team to determine clearly where additional control measures are required.

Example of a table from a WSP used to identify and validate existing control measures, reassess and prioritize risks:

For further information on this module, see the Water Safety Plan Manual (WHO/IWA, 2009).

Module 5: DEVELOP, IMPLEMENT AND MAINTAIN AN IMPROVEMENT/UPGRADE PLAN

Develop, implement and maintain a detailed improvement/upgrade plan to address all significant risks that require additional control. Generally, some improvements can be implemented immediately at little or no cost, while other improvements may require significant resources and more time to implement. Improvement/upgrade plans should allow for “incremental improvement” i.e. step-by-step improvements in risk management, to allow time for planning and for the necessary funding to become available.

Important distinction - Module 5 focuses on documenting new or additional control measures that are required, whereas Module 4 focuses on existing control measures that are already in place.

For further information on this module, see the Water Safety Plan Manual (WHO/IWA, 2009).

Module 6: DEFINE MONITORING OF THE CONTROL MEASURES

Develop and implement operational monitoring plans to ensure that control measures continue to work effectively.

Operational monitoring: Routine monitoring performed to confirm that control measures are working to protect water safety at key steps along the water supply chain

Important distinction – operational monitoring (Module 6) is different from verification monitoring (Module 7). Operational monitoring determines if individual control measures are operating effectively, whereas verification monitoring looks at the WSP as a whole, to determine if it is working effectively to provide a safe and reliable drinking-water supply.

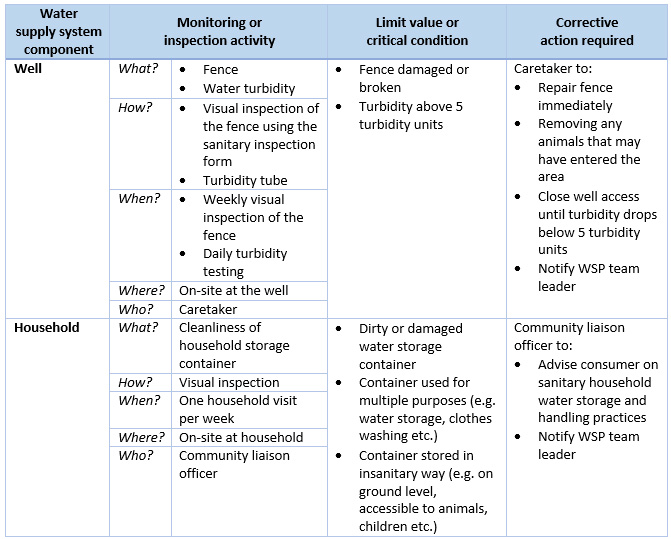

Example of an operational monitoring plan from a WSP:

| Process step | Control measure | What? | Where? | When? | How? | Who? | Critical limit | Corrective action |

|---|---|---|---|---|---|---|---|---|

| Catchment | Fence around wellhead | Physical integrity | At well | Weekly | Visual inspection | Maintenance lead | Fence integrity compromised | Repair fence |

| Water treatment plant | Chlorine disinfection | Chlorine residual concentration | At plant outlet | 4 x daily | Sampling and field testing | Operator | < 0.2 mg/L > 1.0 mg/L |

Adjust chlorine dose as per SOP |

| Distribution/Storage | Vermin proof netting | Physical integrity | At treated water storage tank | 1 x month | Visual inspection | Network operator | Damaged or missing vermin proof netting | Repair or replace vermin proof netting |

| Household | Consumer awarness/education programme | Household drinking-water storage practices | Household | 1 x household per week | Visual inspection | Public health officer | Observation of use of insanitary storage vessel and unhygienic handling | Inform household of appropriate water storage and handling practices |

For further information on this module, see the Water Safety Plan Manual (WHO/IWA, 2009).

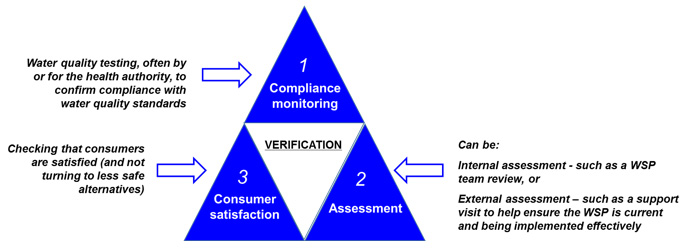

Module 7: VERIFY THE EFFECTIVENESS OF THE WSP

Demonstrate that water quality targets are being achieved (e.g. drinking-water quality standards), consumers are satisfied and the WSP is complete, up-to-date and implemented.

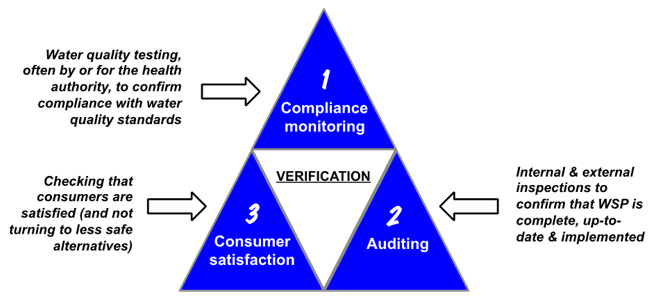

The three key actions for WSP verification monitoring:

Important distinction - verification monitoring (Module 7) verifies that the WSP as a whole is working effectively, whereas operational monitoring (Module 6) determines if individual control measures are operating effectively.

For further information on this module, see the Water Safety Plan Manual (WHO/IWA, 2009).

Module 8: PREPARE MANAGEMENT PROCEDURES

Document management procedures to be followed during normal conditions, incident situations and emergencies. This typically includes both standard operating procedures (SOPs) for key operational activities and emergency response plans..

For further information on this module, see the Water Safety Plan Manual (WHO/IWA, 2009).

Module 9: DEVELOP SUPPORTING PROGRAMMES

Develop supporting programmes that contribute to drinking-water safety. Examples of supporting programmes include operator training and development, consumer education and research and development.

For further information on this module, see the Water Safety Plan Manual (WHO/IWA, 2009).

Module 10: PLAN AND CARRY OUT A PERIODIC REVIEW OF THE WSP

Ensure that the WSP is up-to-date and effective through regular review and, if necessary, revision. This will ensure that new risks threatening the production and supply of safe drinking-water are regularly assessed and addressed and that the WSP is continuously improved. Examples of events that may trigger a review of the WSP include new activities in the catchment, new water supply system infrastructure and updates to improvement/upgrade plans.

For further information on this module, see the Water Safety Plan Manual (WHO/IWA, 2009).

Module 11: REVIEW THE WSP FOLLOWING AN INCIDENT

Review and revise the WSP to reflect lessons learned from incidents and near misses. Consideration should be given to the cause of the incident, emergency or near miss and the adequacy of the response. This information should feedback into the revision of the WSP as part of continuous improvement.

For further information on this module, see the Water Safety Plan Manual (WHO/IWA, 2009).

WSPs for Small Water Supplies at a Glance

Click here to download a complete summary of the 6 WSP tasks for small water supplies.

- Task 1

- Task 2

- Task 3

- Task 4

- Task 5

- Task 6

Task 1: Engage the community and assemble a WSP team

Engage with key community members to generate interest and support for WSP development and implementation. In particular, participation and buy-in from community leaders and decision makers is essential to secure the necessary resources to support water safety planning activities.

Establish a WSP team with strong leadership to develop, implement and maintain an effective WSP. The team should include individuals with the authority to take action to improve the water supply system, as well individuals with sufficient knowledge of catchment activities, water supply operations and water quality. Consider what additional external support may be required, for example, from the local water authority, the local health authority and NGOs.

Document the WSP team, clearly defining the roles and responsibilities for each member of the team.

For further information on this task, see the following WSP resources:

Task 2: Describe the community water supply

Provide a thorough and accurate description of the entire water supply system, from catchment to consumer, with sufficient detail to enable the WSP team and the community members identify hazards and their potential impacts on water safety.

Draw an overview map of the water supply system considering:

- human activities and land-uses within the catchment

- water source(s) being used by the community

- treatment steps (if any)

- distribution and consumer points of use (such as tap stands, water vendors)

- consumer practices, (such as drinking-water collection, transportation, household storage, treatment and handling).

Describe the intended users and uses of the water supply. Discuss the community’s aspirations with regards to water quality objectives - compare this to the water quality achieved in practice, as well as any prevailing water quality standards.

For further information on this task, see the following WSP resources:

Task 3: Identify and assess hazards, hazardous events, risks and existing control measures

Hazard: A chemical, physical or microbial agent that can cause harm to public health.

Hazardous event: An event or situation that introduces hazards to, or fails to remove them from, the water supply.

Control measure: An activity or process to prevent or eliminate a water safety hazard, or reduce it to an acceptable level (also known as a ‘barrier’ or ‘mitigation measure’).

Validation: The process of obtaining evidence that the control measures can effectively control the hazard.

Risk: The likelihood that a hazardous event will occur combined with the severity of its consequences.

Part 1 - Identify the hazards and hazardous events: For each step in the water supply system, consider:

- what can go wrong (for example, what has happened in the past, what may happen in the future)?

- how and why might it go wrong?

- when and where might it go wrong?

Consider sanitary inspections (and their associated forms) to support hazard identification and WSP implementation in small water supplies.

Part 2 - Identify the existing control measures and validate their effectiveness: For each hazard and hazardous event, consider what, if anything, is being done to prevent this from happening? Determine if these measures can effectively control the hazard in question.

Important distinction – Task 3 considers the existing control measures that are currently in place to control water safety hazards, whereas Task 4 considers what additional control measures are needed to effectively manage these risks.

Part 3 - Assess the risks:The risk associated with each hazardous event should be assessed to distinguish between significant and less significant risks. This will allow the WSP team to clearly identify which actions are the priority. Depending on the local context, the risk assessment methodology may range from a more sophisticated approaches (e.g. a risk assessment matrix) to a more simplistic approach (e.g. the WSP team deciding as a group how important is a particular hazardous event).

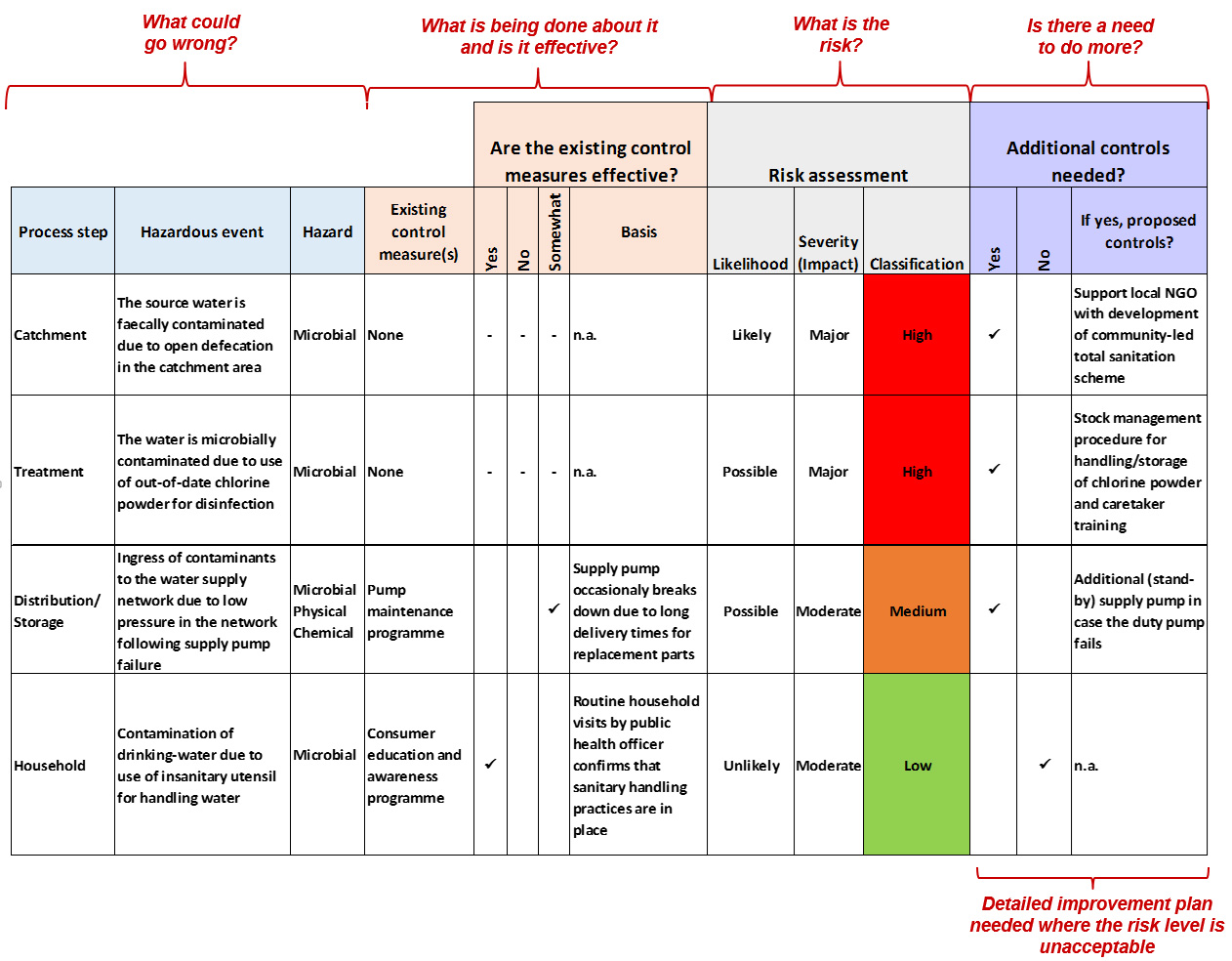

Example of a table from a WSP to document hazards, hazardous events, control measures and their effectiveness, and the subsequent risk assessment using a risk matrix:

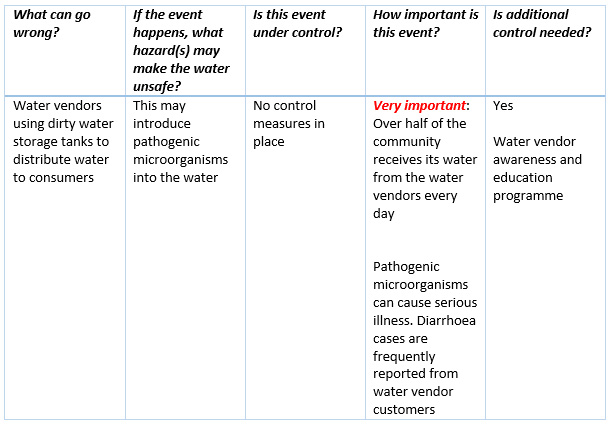

Depending on the local context, this approach can be simplified even further as shown in the following table.

Example of a simplified table from a WSP to document hazards, hazardous events, control measures and their effectiveness, and the subsequent risk assessment using a WSP team group decision:

For further information on this task, see the following WSP resources:

Task 4: Develop and implement an incremental improvement plan

Develop, implement and maintain a detailed improvement/upgrade plan to address all significant risks that require additional control.

An incremental improvement plan allows step-by-step improvement in the water supply system. This approach can identify which smaller improvements can be actioned right away (e.g. exclusion of animals from a communal well area), and which larger improvements are required in the longer term once resources become available (e.g. the provision of a chlorine dosing system for the disinfection of the water supply).

For further information on this task, see the following WSP resources:

Task 5: Monitor control measures and verify the effectiveness of the WSP

Confirm that the water supply is operating as it should be and that the WSP is protecting drinking-water safety and public health. This may be achieved through operational monitoring and verification monitoring.

Operational monitoring: Routine monitoring performed to confirm that control measures are working to protect water safety at key steps along the water supply chain.

Verification monitoring: Confirms that water quality targets or objectives are being achieved and maintained and that the system as a whole is operating safely and the WSP is functioning effectively.

Part 1 – Operational monitoring: confirms that individual control measures are working as intended. Operational monitoring may involve quick and simple visual inspections as well as water quality testing to inform operational decisions. This task involves determining the critical limits (or target conditions) for appropriate monitoring parameters as well as corrective actions to take when critical limits are breached.

Example of an operational monitoring plan from a WSP for small water supplies:

Part 2 - Verification monitoring: confirms that water quality targets are being achieved (e.g. drinking-water quality standards), the WSP is complete, up-to-date and being implemented, and that consumers are satisfied.

The three key actions for WSP verification monitoring:

For further information on this task, see the following WSP resources:

Task 6: Document, review and improve all aspects of water safety plan implementation

Document the status and the level of operation and management of the water supply system to ensure that the WSP approach is embedded in operations and that the WSP remains up-to-date and effective.

Part 1 – Document management instructions: Prepare step-by-step instructions for important operational and maintenance tasks that the operator of the system may easily follow (e.g. how to clean the spring box; how to maintain the chlorine dosing pump). Prepare guidance also for what needs to be done in case of an incident or emergency (e.g. in the event of contamination of the water supply).

Part 2 – Participate in supporting activities: Identify and provide activities to support and contribute to improved drinking-water supply operation and water safety. Examples include caretaker training and consumer education and awareness activities (e.g. an education programme for consumers on safe household water storage).

Part 3 - Regularly review the WSP: Review and, if necessary, revise the WSP regularly and following any incidents to ensure that the WSP is up-to-date and effective and that it reflects lessons learned.

For further information on this task, see the following WSP resources:

The below graphic compares the 11 modules of the Urban WSP approach with the six WSP tasks for Small Water Supplies